- Home

- Rail Tie Plate

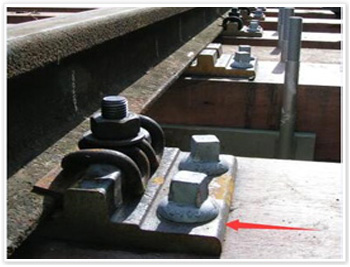

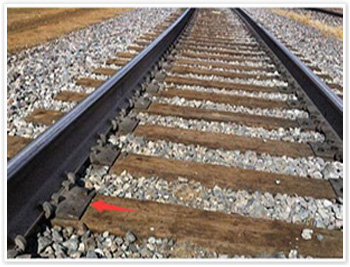

Rail tie plate, also known as base plate or sole plate, is used between rails and sleepers to support the rails and is one of the main components in railway construction.

Rail tie plate is not only used to support the rails, but also to fix the entire rail fastening system. It is usually used with clips, clip bolts, sleeper screws, etc., to bear the load on the rails during operation of the locomotive, and to transfer part of the load to the sleepers. The surface supporting the rails is flat and smooth, ensuring the exact distance between two parallel rails.

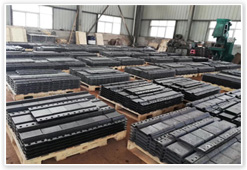

According to the production process, the rail tie plate can be cast, forged and rolled.

1、Rail tie plate by casting

From the point of view of the production process, the casting process is widely used at home and abroad, . The production cost is the lowest. They are used on the rails of UIC60, UIC54, S49, 50kg, and 60kg etc .

Material: Cast Steel ZG35/ZG45

Cast iron QT500-7/QT450-10

Surface: Plain or sandblasted

Chemical composition and mechanical properties are shown in the table

| Steel No. | Chemical Composition (%) | Mechanical Properties | ||||||

| C | Si | Mn | ≤S | ≤P | Yield Strength | Tensile Strength | Elongation | |

| ≥Mpa | ≥Mpa | ≥% | ||||||

| Casting steel ZG35 | ≤0.40 | ≤0.5 | ≤0.9 | 0.04 | 0.04 | 270 | 500 | 18 |

| Casting steel ZG45 | ≤0.5 | ≤0.6 | ≤0.9 | 0.04 | 0.04 | 270 | 570 | 15 |

| Casting iron QT450-10 | 3.4-3.9 | 2.7-3.0 | 0.2-0.5 | 0.07 | 0.03 | 310 | 450 | 10 |

| Casting iron QT500-7 | 3.6-3.8 | 2.5-2.9 | ≤0.6 | 0.08 | 0.025 | 320 | 500 | 7 |

2、Rail tie plate by rolling

In recent years, a large number of customers from the United States and Canada have been demanding rolling tie plates. Based on our rolling expertise and the experience of joint bar rolling accumulated over the years, our factory tried to apply the rolling process to tie plate . so far we have successfully developed tie plate with bases of 5/1/2 inch and 6 inches, widths of 11 inches, 14 inches, 14-3/4 inches and 16 inches. The quality of products is well recognized by customers. Based on this, we received a large number of orders from the United States and Canada, and there are some more varieties that are discussing technology with customers and are ready to develop.

The rolling tie plate has high output and low unit price.

Material: Q235

Surface: Plain

Name | Application | Size | Material | Weight/Kgs | Hole |

Plan 4 #tie plate | 5-1/2 inch rail base width | 7-3/4*11” | Q235 | 5.8 | 7 holes |

Plan 12# tie plate | 6 inch rail base width | 7-3/4*14” | Q235 | 9.5 | 6 or 8 holes |

Plan 13# tie plate | 6 inch rail base width | 7-3/4*14-3/4” | Q235 | 10.6 | 6 or 8 holes |

Plan 21# plate tie | 6 inch rail base width | 7-3/4*16” | Q235 | 11.8 | 6 or 8 holes |

3、Rail tie plate by forging

Compared with rolling tie plates, forging tie plate has low development costs and short development cycles. Our forging tie plates are well received by customers in the U.S. market and orders are constantly coming from the United States.

Material : Q235 , 45#

surface : Plain

Name | Rail type | Size | Material | Hole |

Tie plate | 100-8 | 7*15-3/16 | Q235 | 6 Round holes |

Tie plate | 115RE | 7-3.4*15 | Q235 | 4 Round holes +2 Square holes |

Tie plate | 136RE | 7-3/4*16 | Q235 | 4 Round holes +2 Square holes |

Wechat: +8615901613885

Wechat: +8615901613885