- Home

- Rail Shoulder

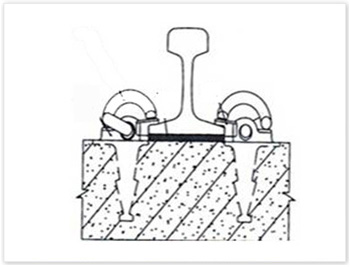

Rail shoulder is a pre-inserted part in a concrete sleeper. It is used together with a rail clip to fix rails. According to different use requirements, Rall shoulder can be completed by casting and hot forging.

1、Rail Shoulder by casting

Rail cast iron shoulders include M.C.I. shoulder manufactured from pearlitic malleable iron and S.G.C.I. shoulder manufactured from spheroid graphite iron. We offer two types of iron shoulders. One is Single Stem Iron Shoulder used in pre-stressed concrete ties and the other is Twin Stem Iron Shoulder used in twin Block concrete ties.

Casting shoulders are pressed in concrete sleeper and assembled with E clip in order to fasten the rail. The material we use is cast iron and the mechanical property and chemical composition of the rail cast iron shoulder are shown below :

| Material | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) |

| QT400-15(GGG40) | 400 | 250 | 15 |

| QT450-10(GGG45) | 450 | 310 | 10 |

| QT500-7 (GGG50) | 500 | 320 | 7 |

| C | Si | Mn | P | S | |

| QT400-15 | 3.6-.36 | 3.0-3.2 | 0.5 | 0.07 | 0.02 |

| Qt450-10 | 3.4-3.9 | 3.7-3.0 | 0.5 | 0.07 | 0.03 |

| QT500-7 | 3.4-3.8 | 2.5-2.9 | 0.6 | 0.08 | 0.025 |

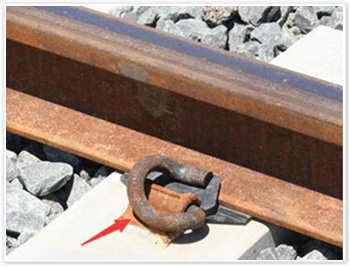

2、Rail shoulder by forging

This rail shoulder is produced by hot forging and used together with fasteners like bolt .and clip , which is put into the concrete sleeper in advance , it is widely used in Russia ,

Material : Q235.35#.45#

Surface: Plain

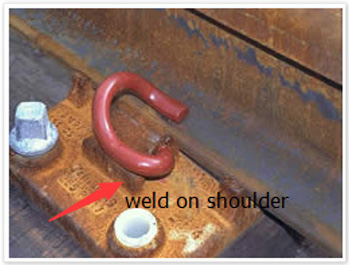

3、 Weld-on Shoulder

Weld-on shoulder is used for the typical position of rail. This rail cast iron shoulder is welded on flat steel plate instead of the standard tie plate and is produced according to AREA standard.

Designed for use with E style elastic rail clips, the weld on shoulder fastening allows customers to fabricate rail retaining units on both steel sleepers and steel base plates.

The weld-on shoulder can also be welded on to longer length steel sleeper sections or bearers for use in the fabrication of switch and crossing layouts where vertical rail geometry is employed. The railway shoulder's ability to be welded in the specific position as dictated by the layout design makes it particularly useful and cost effective in this role.

The shoulder accessories are supplied for specific rail sections with design criteria which ensure that the correct elastic clip toe loading is achieved. Certain shoulders are supplied with milled weld area faces to assist in achieving the necessary weld integrity.

Weld on shoulder Made of hot forging, it is used in places where the standard sleepers are not easy to use. Therefore, it needs to be welded on the tie plate and used together with the elastic clips to fix the rails.

Material : Q235 .35#.45#

Surface : Plain

4、 Rusian rail anchor

Russian rail anchors are put into the concrete sleeper in advance and are used in conjunction with fasteners to fix rails. The process is casting. The material is QT400-15. The mechanical properties of the material are complied with the Russian standard TOCT7293-85.

Chemical composition and mechanical properties are shown in the table below.

Material : Q235 .35#.45#

Surface : Plain

Material | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) |

QT400-15(GGG40) | 400 | 250 | 15 |

Material | C | Si | Mn | P | S |

QT400-15 | 3.6-.36 | 3.0-3.2 | 0.5 | 0.07 | 0.02 |

Wechat: +8615901613885

Wechat: +8615901613885